The Air Car Part 2 - Q & A With Louis Arnoux of IT-MDI

Posted by Big Gav on January 19, 2008 - 3:00pm in The Oil Drum: Australia/New Zealand

Update: I received responses to my follow up questions from Louis - see the end of the Q&A section.

In the wake of my last post on The Air Car (The Air Car - A Breath Of Fresh Air Or A Waste Of Breath ?), IT-MDI's Louis Arnoux made a lengthy comment at the tail end of the commenting period, arguing that we had been overly harsh in questioning the practicality of the vehicle(s).

It’s great to feel the excitement, interest and intrigue about the MDI “air car” as posted on The Oil Drum – Australia and New Zealand. However, a large number of those comments are in my view mistaken and made without the required knowledge and expertise. In this posting I wish to clarify a few matters.

To call the MDI vehicles an “air car” is a misnomer. It is no more an “air car” than a “gasoline car”, or a “diesel car” or an “ethanol car” or a “rapeseed oil car” or a “what-have-you car.” The point being that the MDI engines (there is a whole series of them) are being designed to accept a very wide range of primary energy inputs including fossil fuels, bio fuels, waste heat recycling from other processes and thermal solar energy. Transport is only on aspect of the applications of the MDI technology. Power generation at the point of use, on customer premises is another. Power generation applications are at least as important as the transport applications.

“Is it for real?” many people ask. ...

As few people were likely to be following the comments at that point, I asked Louis if he would like to do an interview to answer some of the questions we had about the MDI technology.

Question: What equipment would be required for fast refills at service stations ? How much would the equipment cost, and how much to you estimate it will cost to refill the car ? What are the power requirements for the compressors ?

Answer: In the Australasian applications we do not intend to use compressed air refilling point to any significant extent. It is important to realise that the main version of the MDI engine is designed to run in multi-fuel mode. That is to say that (1) it makes it's own compressed air through the burning of a fuel that takes place inside a heater/combustor located outside the engine. Because the primary energy input takes place outside the engine, it is possible to use any fuel, petrol, diesel, natural gas, LPG, or preferably "green" biofuels like rapeseed oil, ethanol from sugarcane, and so on.

Because the system (compressed gas engine and external heater/burner) is much more energy efficient than an internal combustion engine the amount of biofuel required per 100 km is considerably reduced. The present system is capable of running on 2 litres per 100km. As far as I know no other engine can achieve this.

In cases where a compressed air refilling station is to be used, such as possibly for a fleet of taxis or mini buses operating in a CBD, the compressor is a standard commercial unit combined with a bank of compressed air bottles. The refilling station is very similar to that used for CNG (Compressed Natural Gas) used to operate converted cars or buses, except that in our case the gas is air instead of being methane. It takes 2 to 3 minutes to refill the bottles in a MDI car. I am not prepared to provide cost or power requirement information as this, of course, is commercially sensitive. Simply, as MDI likes to stress, the cost of operating the first commercial model, code named for now the OneCAT, is expected to be €1 per 100 km, i.e. about AU$1.70 or NZ$1.90 per 100 km.

Question: When will construction of the manufacturing facility in Melbourne commence?

Answer: That depends on investment levels and MDI's delivery timetable. At present rate I am expecting establishing a first manufacturing facility during the second half of 2008 and being in full production in 2009. Initially, our focus is going to be on producing power generators, then we plan to move on the automotive applications.

Question: When will air cars first appear on Australian roads ?

Answer: MDI plans to unveil its OneCAT before the end of January 2008. I plan to show case one in Australia towards July 2008.

Question: Is the Melbourne plant the only one planned ? Some articles have mentioned three manufacturing plants in Australia / New Zealand.

Answer: The joint IT MDI business model is to manufacture at or close to the point of sale in small networked factories. We are planning a substantial number of such factories distributed throughout Australasia. We plan to complement this network of factories with a few hubs. We plan to establish the first of those hubs in Melbourne.

Question: How long do you believe it will take to obtain approval from the various Australian state vehicle licencing Authorities ? Has crash testing been undertaken and approved by Australian authorities ? What would happen if an air tank is ruptured ?

Answer: MDI is constantly monitoring regulations world wide and designing each feature of its vehicle to meet the most exacting of all specifications. So I do not expect any significant issue to obtain approval in Australia. The OneCAT will have very innovative design features concerning crash safety. Nothing much would happen in case of a tank rupture. The tanks are underneath the car floor, built within the chassis frame and design to bleed towards the ground in case of a rupture; so just a big "pshiiiit".

Question: How well does the vehicle handle strong cross winds given its light weight ? Has any testing been carried out in this area ?

Answer: It works very well. Weight is only one of many factors affecting handling in cross winds.

Question: If the car can drive up to 4500kms on one tank and the stated economy is 2litres/100km the implied tank capacity is 90litres. This is somewhat larger than the standard fuel tank. Where is this situated in the Australian models?

Answer: Several pieces of information are conflated in the above query. MDI is designing more than one car. The above refers to a bigger model and to our plans to demonstrate the capabilities of the technology, for example, by driving from Perth to Brisbane on one tank full, possibly with an adapted tank.

The OneCAT is being designed to have an autonomy of about 150km when run purely on air within an urban centre and an autonomy similar to that of a contemporary small car when run in multi-fuel mode.

Question: There have been many reports over the years that production of the Air Car will begin shortly - for example, in 2000 this BBC report (http://news.bbc.co.uk/2/hi/africa/988265.stm) claimed cars would soon be rolling off production lines in France then South Africa, with a raft of countries to follow afterwards - what obstacles were encountered back then and have these all been overcome ?

Answer: In my view, the two main obstacles have been (1) that some parties do not like the prospect of a revolutionary energy and automotive technology and have been keen to stop it, slow it down, or take it over, and (2) low investments levels because parties able to provide larger levels of funding by and large did not know how to evaluate an initiative that was so out of what they were use to (so-called change agent or disruptive technology) and/or wanted to take it over. As is often the case and up to 2007, both MDI and my own company IndraNet technologies (the IT in IT MDI - Energy Ltd) have progressed entirely with the financial support of relatively smaller investors and small individual investments. Both factors combined has meant many delays and much slower progress than would have been the case if the companies had been left to do their work in peace and had been suitably funded. The first commercial models could have been on the roads at least 2 years ago. However, we are resilient people and now things are getting very exciting.

Question: It is stated that the car has a top speed of 110kph. It is implied this is achieved using only compressed air as the power source - is this correct ?

Answer: The 110 km/hour speed is by choice to fit within speed regulations for the small market entry model. This is not the maximum speed that can be achieved. Where regulations allow it, it is expected that subsequent larger models will be produced matching speed performance of contemporary cars. Running purely on air within a CBD, the car is designed to cruise at around 50 km/hour and will be able to go to 110 km/hour (obviously at such higher speed the air reserves get used more quickly). It is important to note that the MDI engines have very flat torque and energy efficiency curves, meaning that torque and efficiency are similar at around 200 revs and 4,000 revs. From this it ensues that an MDI car equipped with a 40kW MDI engine can have the same acceleration feel as that of a mainstream car with a 150 kW internal combustion engine and a complex and heavy clutch and gear box assembly.

Question: The Age mentions a range of 150km using compressed air. Is that at a specific speed, and if so, what is this speed? What range would the car have if it was used on freeways at a speed of 110kph?

Answer: As noted above the 150 km is for in town driving at a moderate speed around 50 km/hour. The actual range depends very much on people's driving patterns. People who very often accelerate and stop abruptly would use up their reserves much faster than less aggressive drivers. However, at any time, the car can be switched back to multi-fuel mode and run burning a fuel and while driving it can recharge its compressed air storage. In other words the cars are being designed to never run out of compressed air.

Question: How noisy is the car compared to a normal passenger car ?

Answer: The commercial version are expected to be similar to current passenger cars or less noisy. The prototypes that have been shown on numerous TV shows were not muffled to any significant extent, simply for ease of running tests. They are not representative of the final noise levels in commercial series products.

Question: How noisy is the onboard air compressor when it is being used to refill the tanks from an electrical power outlet at home ?

Answer: The system is being designed to be very quiet. In the main version the system (that includes a variable speed reversible power generator/electrical motor) reverses as a compressor. There is no separate compressor.

Question: The article in The Age talks about a hybrid mode where "the air is heated externally and incorporated with a fuel source, such as ethanol or diesel" - can you explain how this works ? Could you also explain the 'MDI thermodynamic cycle' and how it creates the claimed efficiencies ?

Answer: This refers to what I outlined above. The engine takes air from the outside and compresses to 30 bar. It pushes this 30 bar compressed air through the external heater/combustor where the air is heated at constant pressure by a flame. A gas heated in this fashion expands. So through the application of heat, each cubic centimetre of air at 30 bar injected in the heating module is expanded to 3 to 5 times.

This expanded air is then returned to the engine where it pushes the pistons. The overall energy balance is very positive (power available at the crankshaft less power used to compressed the air intake). The design of the engine itself makes it twice more energy efficient than an internal combustion engine. The external combustion takes place in a steady fashion (no explosions and in internal combustion engines), at much lower temperatures (less than 860oC instead of around 2000 oC) and in an excess of oxygen (which means a very lean and clean combustion that does not produces any significant levels of uncombusted particulates or NOx pollutants).

The fact that the combustion is external means that one has a wide choice of fuels without having to change the engine, only the fuel supply parameters to operate the burner require adjusting when changing from one fuel to another. This is done through a computerised system.

Question: Could you explain the relevance of 'advanced magneto-caloric quantum mechanic effect' and how it is used to 'reduce intake temperature and further enhance energy efficiency'.

Answer: This concerns the next upgrades of the system. What governs the amount of power an engine can produce is the temperature difference between the hot and cold side. In the case of the MDI technology, since the combustion takes place outside the engine one has a much better and easier control of both the hot and cold sides. One can use and advanced heat pump (which is what the magnetocaloric effect is used for) to substantially cool the air intake.

This means that one can also lower the top temperature to be achieved on the hot side. This makes it substantially easier to recycle waste heat from other processes (e.g. in industrial applications for distributed power generation) and/or from thermal solar energy including from ambient heat in the atmosphere (hence calling this version "solar augmented"). Through such upgrades MDI expects to bring fuel consumption to 1 litre/ 100 km or less.

Question: Given that a large number of patents have been secured, are there plans for the technical details of the car to be made publically available ?

Answer: Patents that have been granted are accessible to anyone. However, patent applications into actual commercial products entail a considerable amount of know how that is commercially sensitive. Details will be unveiled over time, having in mind such sensitivity.

While there have been many incremental improvements or variations to internal combustion engines (e.g. various petrol, diesel, or rotary engines) since they were invented over a century ago, during all that time there has not been a single major new breakthrough. In my view MDI is one. There amy be others in the future. However, I do not know of any in sight capable of achieving what the MDI system is already achieving and at similar extremely low costs.

I hope the above will assist in gaining a better understanding of the MDI technology, in addition to what I have already posted.

Louis' responses indicate that the first product IT-MDI will be marketing is actually a power generator, with cars to follow at a later stage, so I suspect we won't be seeing air cars on Australian roads in the near future.

I've sent through some follow up questions, in particular asking for a roadmap indicating which products will be available when and what their capabilities will be. At this stage I haven't received a response.

Update 20 Jan - responses received

Question:Tata have been reported as saying it will be at least 2 years before they produce an air car. Do you expect to get to the market before Tata ?

Yes. We are in a joint venture with MDI.

Question: Could you give me a "roadmap" outlining the dates of the product releases you are planning and a brief description of each product. I think some of the confusion generated by the press coverage is due to a range of different products being described without any clear differentiation between the different versions.

We have entered the productisation phase, i.e. the use of new technology to generate new products. With pioneering technologies, timetable must remain very flexible as one cannot rely on the same support systems as in the case of well established products. We aim to have a first manufacturing facility established in Australia in 2008. Our plan is to first produce power generators for distributed point-of-use electricity generation (such as for emergency back up units, and replacing UPSs, remote locations, farms, recycling of waste heat in industrial settings, and communities aiming towards sustainable independent lifestyles). We then plan to begin producing a small market entry vehicle code named for now OneCAT by MDI. Over the ensuing five years we intend this to lead to production of an expanding range of vehicles, including family cars, utility vehicles, tractors, forklifts, trucks, buses, boats and light aircrafts.

Question: Can you describe the target market for the power generators you plan to manufacture first - and the expected capabilities and price for these ?

Please see above. The pricing is to be set up to be competitive with existing products or services in each instance. for commercial reasons I cannot expand on this at this stage.

Question: Can you describe how the external heat source is integrated into the design and how the multi-fuel version increases the range of the car?

We plan to post soon on our www.itmdi-energy.com website a small video clip showing a multi-fuel MDI engine in operation that hopefully will make clear how the external heat source is integrated with the MDI engines.

The range of a vehicle is governed by the amount of energy stored on board in whatever form. A fuel has a much greater energy density than stored compressed air. By burning a fuel, preferably renewable, the MDI system makes its own compressed air. The system is currently capable of achieving around 2 litres of petrol per 100km. So on a suitably sized tank (e.g. 60l) one can drive for about 3,000 km versus about 150km on stored compressed air.

Question:Can you describe how the engine is used in refilling the air tanks both in a stationary and mobile mode?

The new MDI engines have a set of pistons built in that are used to compress air in three stages to recharge the compressed air bottle(s) at around 300 bar.

End update

Nevertheless, the Air Car continues to get a lot of press, with sites like TreeHugger, AutoBlogGreen and Celsias pointing to this BBC video on the vehicle. Plenty Magazine also has a report.

Tata are the MDI licencee that tends to get the most press attention - however the company recently released a very cheap petrol fueled vehicle - the Tata Nano (or "Peoples Car") - and have been reported as saying it will be at least 2 years before they produce an air car.

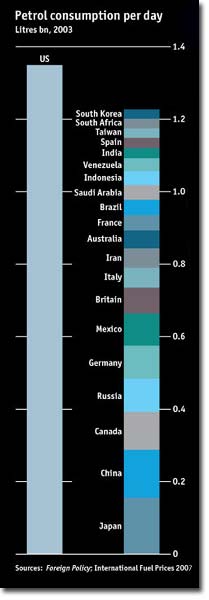

The Tato Nano has come in for a lot of criticism since its release, with people expressing concern that if hundred of millions of new vehicles appear on the roads, as the emerging middle classes of Asia can now afford their own cars, we will rapidly accelerate the problems of peak oil and global warming.

The Tato Nano has come in for a lot of criticism since its release, with people expressing concern that if hundred of millions of new vehicles appear on the roads, as the emerging middle classes of Asia can now afford their own cars, we will rapidly accelerate the problems of peak oil and global warming.

Pavithra Sankaran at Celsias had a look at some of the issues surrounding the Nano, and pointed out "If the Nano does jam traffic, people will demand better road networks. If petrol prices go up, they will use public transport. As for rising emissions, I cannot see people caring as long this graph stays the way it is."

WorldWatch has some interesting thoughts about those criticising the potential impact of the Nano while ignoring the much greater impact cars are having elsewhere.

One car gets 46 miles per gallon, features fancy accessories, and sports two engines with a combined 145 horsepower. The other car reportedly gets 54 miles per gallon, runs on a diminutive 30-horsepower engine, and is positively spartan in its interior trimmings. The first is a darling of the environmentally conscious. The latter is reviled as a climate wrecker. These two vehicles are the Toyota Prius and the newly unveiled Tata Nano, dubbed “the people’s car.” Is there a double standard?

Advertised as the world’s cheapest car, the Nano is a no-frills automobile designed by Indian conglomerate Tata to be affordable for millions, possibly hundreds of millions, of people who are newly joining the middle class in India and elsewhere in the developing world. Such mass sales might overwhelm halting efforts to ward off catastrophic climate change. As Indians (and others) join the love affair with the private automobile, many in the West are suddenly aghast at the prospect of Nano becoming a household term like Chevy or Mercedes. The German weekly Der Spiegel termed it an “eco-disaster.”

Indeed, transportation has the fastest growing carbon emissions of any economic sector. Proliferating numbers of automobiles are a key reason. More than 600 million passenger cars are now on the world’s roads, and each year some 67 million new ones roll out of manufacturing plants.

But amid the finger pointing, let’s remember who has driven the planet to the edge of the climate abyss. People in Western countries and Japan—less than 15 percent of the world’s population—own two-thirds of all passenger and commercial motor vehicles in the world. Although they are rapidly expanding their fleets, India and China, with a third of the world’s population, so far account for only about 5 percent of vehicles. In 2005, China’s ratio of motor vehicles to population was at about the level the United States had reached some 90 years earlier. India’s ratio is less than half that of China.

Westerners not only have far more cars, but the distances they drive are also 3–4 times longer on average than those of Indians and Chinese. The United States alone—where monster SUVs roam and driving is considered a birthright—claims about 44 percent of the world’s gasoline consumption. Fuel economy has stagnated for a quarter-century as cars grew larger, heavier, and more muscular. Here in New York, a Nano might be mistaken for a golf cart.

So if it’s true that Asia’s (and Latin America’s and Africa’s) teeming billions can’t indulge in the same reckless habits as Westerners, then neither can Americans, Europeans, or Japanese. Delhi and Beijing know hypocrisy when they encounter it. Nonetheless, they have good reason to take action irrespective of what Western countries say or do. Residents of many Asian cities are exposed to a lethal brew of sulfur and nitrogen oxides, particulates, and toxics from motor vehicles of all stripes. Breathable air is every bit as important as climate stability.

Leaner engines and cleaner fuels are essential. The Nano may well be a cleaner option than the highly polluting motorcycles, motor rickshaws, and diesel buses (and many of the Western-designed cars) already clogging India’s roads. But the mass market that Tata is hoping for will render putative gains ephemeral.

All countries need to seriously rethink their transportation policies. Such an effort has to go far beyond the pursuit of alternative fuels and even beyond making cars more efficient. Denser cities and shorter distances reduce the overall need for motorized transportation and make public transit, biking, and walking more feasible. Those who will never be able to afford a car will have more options instead of being marginalized by the onslaught of private automobiles. ...

Moving back to the topic of the Air Car, Tyler Hamilton from Clean Break has the best review of the vehicle that I've seen, published in MIT Technology Review.

A French-designed car that's propelled by compressed air and claims speeds of more than 60 miles per hour is expected to go into commercial production as early as this summer, although skeptics of the technology aren't holding their breath.

Using compressed air, they argue, may mean zero tailpipe emissions, but it's unlikely to provide enough range or speed to appeal to the masses, particularly in North America. "Compressed air does not contain much energy--that's the killer," says Larry Rinek, senior research analyst for automotive technologies at consultancy Frost & Sullivan. "This is more a nice garage project for a Popular Science subscriber." ...

The Air Car was supposed to hit the streets years ago, but its release always seems just around the corner. MDI announced in 2002 that the cars would be used to replace taxis in Mexico City, but nothing resulted.

Tata's involvement this time around, combined with the fact that oil recently hit $100 a barrel, could change the game. India's largest automaker announced last February that it had struck a deal with MDI to further develop and refine Negre's compressed-air engine technology, with the intention of producing and selling the emission-free cars in India. It has since been reported that Tata invested nearly $30 million in MDI as part of the agreement. ...

The Air Car may do better than fuel-cell cars, but experts say that using grid power to charge a battery-powered electric vehicle is much more efficient than using electricity to compress and store the same amount of energy in a tank. "The main problem is that air gets hot when you compress it, so much of the energy input goes into raising the temperature of the air as you try to raise the pressure," explains Doug Nelson, a professor of mechanical engineering and an expert on advanced vehicle systems at Virginia Polytechnic Institute. ...

At the core of all CAT models is a four-piston engine powered by compressed air that is stored in tanks at 4,500 pounds per square inch. The lightweight tanks, a thermoplastic container surrounded by a carbon-fiber shell, are made by Airbus Industries and hold nearly 3,200 cubic feet of air.

To propel the vehicle, compressed air from the tanks is injected into a small chamber, where it expands and cools. This expansion drives a downstroke of the piston. But as the ambient temperature begins to reheat the air in the first chamber, that air is forced into a second neighboring chamber, where it expands again to drive an upstroke. Using ambient heat helps capture more of the energy in the compressed air, ultimately improving the efficiency and expanding the range of MDI's Air Car. And compared with four-stroke combustion engines, in which half of the strokes are wasted to pull air and fuel into the chamber, the air engine makes use of every stroke.

Ulf Bossel, a mechanical engineer consulting in Switzerland and organizer of the European Fuel Cell Forum, is cautiously optimistic. "I think there's something to it," says Bossel, one of the few who has performed a comprehensive analysis of MDI's approach. Even though one of MDI's compressed-air tanks would carry the energy equivalent of just one gallon of gasoline, the use of that air in the engine is 90 percent efficient.

The energy balance would improve substantially, he argues, if the compressed-air systems located at filling stations or in car owners' garages were designed so that any waste heat during compression could be captured and used to produce domestic hot water, for example. If the compressors could interact with the grid and be programmed to only compress and store air during off-peak hours, or when solar and wind energy are in greater supply, the emissions profile of the Air Car would also improve.

"If you use clean electricity, it's an absolutely clean system," says Bossel, adding that compressed-air systems, despite being less efficient than battery-powered cars, have the advantage of being simple, cheaper to manufacture, and unconstrained by the degradation problems associated with current battery systems. "Still, there are some thermodynamic tricks you have to do," he says.

To increase the range of the vehicle, MDI is also coming out with an optional dual-mode system that allows the car to run on fossil or biofuels--either when its speed exceeds 35 miles per hour or when the compressed-air tanks are empty. When in fuel mode, the car's moto-alternator refills the tank with compressed air as the vehicle moves. ...

The first CAT car to be produced is called the OneCAT, a "utilitarian" car for urban and rural driving that's specifically designed for use in overcongested cities and priced in a range ($5,100 to $7,800) within reach of consumers in a developing economy, such as India.

The ultralight bodies of the vehicles would be made of glued-together fiberglass and injected foam, and the aluminum chassis would also be glued, not welded, to simplify manufacturing.

Before production of the CAT can begin in India, likely followed later by Spain and Australia, MDI says that it must start mass production of the cars at its factory in France. A spokeswoman at MDI's marketing office in Barcelona says that this will likely happen in September 2008.

Gav,

Thanks for your interesting articles on the MDI Air Car.

Whilst there is a lot of criticism about the compressed air storage on the vehicle, and the limited range, when used in autonomous mode, I believe that Louis Arnoux is shifting the project emphasis towards the external combustion mode.

External combustion engines are not new, they include steam and hot air engines. They predate the internal combustion engine by centuries, but it was not until Newcomen's reciprocating atmospheric steam engine of 1712 before they really got moving.

Air engines include Stirling engines, Ericsson engines and engines that use the Brayton and Joule thermodynamic cycles. All of these predate the IC engine.

The MDI engine is best describes as an open cycle Ericsson engine, and relies on the fact that it takes less work to compress air at a low temperature, than is produced when the air is expanded at a higher temperature. The energy need to produce the higher temperature comes from burning a conventional hydrocarbon fuel.

The simplest Ericsson engine consists of an air compressor, a tubular heater - heated by a burner, and some sort of expansion device, which can be rotary expander or reciprocating piston in a cylinder. The output shaft of the expander is mechanically coupled to the compressor shaft. The exhaust is slightly heated fresh air at above atmospheric pressure - ideal for force-draughting the burner.

There is theoretically no need for the storage of the compressed air, compressor and expander can work as a heat engine without it.

It does however, offer an energy storage buffer and would allow the air engine to run more efficiently when powering a vehicle under widely varying load conditions. It also allows a certain amount of vehicle autonomy before you have to light the furnace heater.

The key advantage of air engines is that the source of heat can be derived from burning any available fuel - not restricted to common liquid or gaseous fuels, but solid fuels, biomass, firewood, woodchips, biogas etc.

Using a solar concentrator, an air engine can derive its power from focussed solar energy. Ericsson himself, demonstrated a solar driven water pump in the 1880s.

The efficiency of the air engine is questionable, however. It is likely to fall in the range of 10% to 20%. So it does not make good sense in a vehicle application, where you end up throwing away 80% of the energy contained in the fuel as waste heat.

A better application would be domestic combined heat and power or micro-CHP, where at least the energy rejected by the engine can be used for home heating.

Some European manufacturers are already developing CHP products based on external combustion engines.

This sort of technology would pair well with waste digestion or biomass gassification. Its likely you could have the engine in your garage and batteries in your car or bike. The engine would operate during peak times providing you with all the heat you needed, then the batteries would charge overnight from off peak electric / wind.

Using wind to power air compression directly without generating electricity is an interesting idea,

these guys http://www.generalcompression.com have a good idea, but I see a smaller domestic model. Would be cheaper than an electricity generating turbine, and the pressures/ volumes would be much reduced compared to the larger system.

I like this ericson engine -if it is real. That sort of efficiency would be a good match to a hybrid vehicle, which is what the descibed air-car strongly resembles. I too doubt the energy storage efficiency of compressed air, the stated 10-20% number seems to be in the right ball park. Of course if this "ericson engine" is real and practical it could be used to charge the batteries of an electric hybrid. This would likely be more costly, but would give outstanding fuel economy.

I'm pretty suspicious of this whole venture however. I could make arguments like if it is such a good idea, how has it been around so long without a product? That line about "advanced magneto-caloric quantum effect" strikes me as pure garbage (I have a degree in astrophysics) -if they actually made that statement, I would consider this to be almost certainly an investment fraud.

Yes they did use the phrase advanced magneto-caloric quantum effect. Look in the last paragraph of http://www.itmdi-energy.com/information/solutions.html

I received responses to my follow up questions from Louis :

Question:Tata have been reported as saying it will be at least 2 years before they produce an air car. Do you expect to get to the market before Tata ?

Question: Could you give me a "roadmap" outlining the dates of the product releases you are planning and a brief description of each product. I think some of the confusion generated by the press coverage is due to a range of different products being described without any clear differentiation between the different versions.

Question: Can you describe the target market for the power generators you plan to manufacture first - and the expected capabilities and price for these ?

Question: Can you describe how the external heat source is integrated into the design and how the multi-fuel version increases the range of the car?

Question:Can you describe how the engine is used in refilling the air tanks both in a stationary and mobile mode?

This car is really neat! It has everything we could ask for, if we are willing to live within its limitations. Known technology, reasonable cost, no degrading parts like batteries, nothing expensive that would need to be replaced, like batteries, no pollution in the inner city core when driving, free Air Conditioning as a byproduct, could heat my hot water tank while I charge it up at home, etc. What is not to really like? Every TODer should be behind this. It will not run into any resource limitation like Lithium Ion batteries will. No one will want to steal it (nothing really valuable in it) but there will sure be a black market in the future for Lithium Ion power packs!

From time-to-time I have used compressed air tools in my work. I have always been impressed with their simplicity, versatility and power.

Thanks everyone for all your hard work on the air car articles. Maybe they will be in full production soon and you can win that X-Car competition for $100 million(?).

==This car is really neat! It has everything we could ask for, if we are willing to live within its limitations.==

Those limitations being a car which goes 30mph and has a 90mile range.

Thats some pretty beefy limits.

==nothing expensive that would need to be replaced==

Except for the entire car body, since it's made out of a single cast carbon-fiber mold.

The air tank itself is also carbon-fiber.

==It will not run into any resource limitation like Lithium Ion batteries will.==

Oh really?

http://greyfalcon.net/biolimits.png

Besides which, a Zebra battery for instance, operates off of Aluminum and Salt.

Can ya beat that?

You make the mistake of assuming that you need lithium ion batteries.

When there are innumerable battery chemistries, and additional chemistries afforded by ultracapacitors.

Especially considering this "Air Car" is actually a hybrid.

Wouldn't it make more sense to compare it to a Series Plugin Electric Hybrid.

Where as the cost of the battery is greatly reduced.

Now if we want to go low-tech/low-cost, then how about a ultracapacitor-plus-lead-acid battery?

http://www.greencarcongress.com/2008/01/csiro-ultrabatt.html

I don't see it that way. A car like this is perfect for the city. If everyone wants exactly the type of car they now have, it won't happen. The same company that is working on this has made the $2500 car for India. I think they know what things will cost. The air tanks are here and now with no moving parts. They aren't that expensive. But batteries (that don't exist yet) will be expensive. Same for ultra-capacitors. They don't exist yet and will be expensive. This car has real possibilities. It is working today. Nothing about it is exotic.

This same company hasn't produced the $2500 car for India. It was produced by Tata Motors. Tata have some sort of agreement with MDI in regard to MDI technology but, as noted in the posting, Tata do not expect to produce an 'air car' for at least two years.

As far as I know the air car, except for a few prototypes, is not working anywhere today and since 1995 has been only a couple of months away from being commercially released.

==The air tanks are here and now with no moving parts. They aren't that expensive. But batteries (that don't exist yet) will be expensive. Same for ultra-capacitors. They don't exist yet and will be expensive.==

Ah good point.

I guess I should say "SuperCapacitor"

Like those Produced by Maxwell Technologies.

They don't have large storage, but they do have quick storage.

Thats the reason you would have a lead-acid battery mixed with a super-cap.

So you can get the benefits of both quick recharge (for regenerative braking) and a decent volume of storage.

I'd hardly call that mixture "Exotic".

_

And anyways, battery production tends to have a massive "economies of scale" price reduction.

Much in the same way as microprocessors.

On the subject of mixing supercapacitors with lead batteries, check out this report at GCC on a CSIRO initiative:

http://www.greencarcongress.com/2008/01/csiro-ultrabatt.html

You can also see the AFS Trinity VUE hybrid using supercapacitors to increase battery life. They have submitted a provisional patent on their design and are trying to get auto companies interested.

http://www.greencarcongress.com/2008/01/afs-trinity-unv.html

My idea of a perfect city is one where you don't need any kind of car at all.

Yes, a walkable city would be great. But we have what we have. A few miles South of where I live in Florida is Sun City Center, a retirement community. They use golf carts to get around. It works well for them, but a little beefier car might be better suited to their needs. It would allow them further range mobility than a golf cart, along with better accident protection.

A few other thoughts on the air car: With a pressure outlet you would be able to run air power tools and not need an electric outlet. You could run a generator with the air power in case you needed to. With free air conditioning as a bonus, the car will really work well in the South, like where I live in Florida. I like that idea. The car seems ready-made for DIY projects and garage inventors. We will see what the market thinks after it goes on sale. I hope it is a success. It would seem to have a niche market if it can get established before battery power is able to.

What are the plans to bring it to the US? How many changes would be required to meet crash and other standards?

I think the range and so on are fine. My main concerns are two.

Firstly, as my back-of-envelope calculations showed, if the compressed air is supplied by electricity got from coal-fired stations (and that's more than half world electricity today), then the per kilometre emissions are about the same as the average Western car. So you're just moving the emissions from tailpipe to a chimney somewhere.

Of course that could be easily solved by using renewable energy, so this is just another demonstration of the "there is no single solution" principle. We need to do a few things in combination to solve our problems.

Secondly, and really more importantly, these guys are always just about to mass produce the thing, but it just doesn't happen. Now, the boss naturally blames everyone else, but you have to wonder - is every potential investor narrow-minded, stupid, and unable to appreciate their supposed genius? How many countries have they been to, how many people have they spoken to? Is it more likely that all those people were stupid, or that something about the company or the design puts them off?

Is there some fundamental flaw of the car's design or the company's organisation that has caused this long delay? In other words, do they have their shit together?

I totally agree with the sentiments expressed in your second point. However, in regard to the range and so on I have grave doubts. It appears the only source for these ‘facts’ are the company’s various websites and I have major concerns about a company that is linked to, or produces, a website like http://www.thefuture.net.nz/index.htm. By the way, I really like Louis’s conspiracy theory arguments as to why the car is not rolling off production lines around the world and his typical marketing response to questions on crash testing, etc.

Talking about getting their shit together, people might also like to take a look at some of Louis’s other ventures. A good starting point is http://aardvark.co.nz/daily/2001/0216.shtml from there go to http://www.nzherald.co.nz/section/3/story.cfm?c_id=3&objectid=10115833.

I don’t have the right sort of technical background in this area and I may be completely off track but I’m hoping some technically minded poster can point me in the right direction.

• It would seem to me that if a full tank is at a pressure of 30 bar this pressure would reduce as the volume of air in the tank reduced, is this so?

• Is it feasible for an engine of this type to compress air to 30 bar with the only energy source being an external heat source?

If it's an Ericsson cycle, you could theoretically use the energy input to pump up the pressure in the reservoir. That's what happens to an Ericcson motor with no external load.

Is Louis Arnoux claiming that his engine gets more energy out of the compressed air than the energy that went into compressing the air? If so, isn't this another perpetual motion scam?

I'm assuming he means that it is efficient in the use of the stored energy, not that it magically creates energy out of thin air.

I'm not planning on covering any zero point energy schemes (well - not at TOD anyway :-)

Well he talked about energy balance and about the power at the crankshaft after removing the power to compress the air. It sure sounds like he's talking about magic.

It's not "magic", it's an "advanced magneto-caloric quantum mechanic effect".

How dare you doubt him?

Anyway, let's break it down.

The "advanced" bit is just fluff. Is there a mid-level magneto-caloric quantum mechanic effect? An elementary magneto-caloric quantum mechanic effect? A professional magneto-caloric quantum mechanic effect? A kindergarten magneto-caloric quantum mechanic effect?

The "magnetocaloric" effect is where certain materials in a changing magnetic field heat or cool. The "quantum mechanic" part refers to the subatomic stuff going on which produces the magnetocaloric effect. But he didn't need to say that, he could just say, "magnetocaloric effect". It's a bit like talking about flame as an "exothermic entropic plasma". Strictly-speaking correct, but a bit high-falutin', and in the context of someone trying to sell you something, well...

The problem is that the magnetocaloric effect takes place mostly in materials at low temperatures. Like, liquid nitrogen low temperatures. It's a bit like superconducting in that way.

Some near-room temperature tests have been done, but nothing spectacular or cheap. The other problem is that you get at best 3 or 4C of temperature change for each Tesla of magnetic field. For magnetic fields of above 2T, you need big-arsed superconducting magnets cooled by liquid helium. So you're not going to have one in your car.

People have been studying this effect for some decades, and as yet no commercial application exists.

So exactly what this guy is blathering about I'm not sure. Again, the lack of real details with a few fancy words tossed in is pretty suspicious. Just look at his response when Gav says, "well, if it's all patented, then you can tell us all about it, yes?"

Smells fishy to me.

Reading your post reminded me of a radio show talking about a group of Cambridge researchers who were working on a refrigeration system based on the magnetic phase transitions (yes, this is the magneto caloric effect). A physorg article is available here. They are apparently working towards a commercially available fridge technology that works at usable temperatures.

My guess is that the effect is used to reduce compression heating resulting from the filling of the air tank.

Cobalt is in limited supply at present. If we could just invent a cheap way to get (high cobalt) manganese nodules off the bottom of the South Pacific ocean...then this might be practical.

If you watch one of the air car videos, the narrator gets carried away when he talks about a compressor that they have . He implies that you could just connect one to the other and have free energy. Some physics people need to talk to that person before he goes on mic again.

Coming to this REALLY late, but...

That is my peeve about this whole thing. Practically all of the efficiency claims appear to be either obfuscated or half-truths; for instance, the claim of 2 liters per 100 km appears to be just the liquid-fuel consumption and ignores the compressed air. The real efficiency would be measured in pressure-sustaining mode, when the engine is replacing all the compressed air it uses. If this is what the engine actually achieves, why don't they just come straight out and say so? All the doubletalk leaves me smelling a rat.

It may be possible for the engine to do this, given that it has large energy storage and can meet acceleration demands that way rather than being oversized and taking higher friction losses most of the time. Still, I am very doubtful; the relatively low temperature means low Carnot efficiency. Last, a tiny diesel engine in a small car can easily beat 2l/100 km fuel consumption, as VW proved with its 1 liter test car. And didn't the diesel Polo TDI achieve 3l/100 km with considerably more power?

These claims, even if true, may be a whole lot less impressive than they are made out to be.

What we have here is a failure to communicate!

As I understand it, the major claim here appears to be that the company has developed an external combustion engine, the efficiency of which exceeds 100 mpg when installed a small vehicle costing under $10,000. When operating stand-alone, like all external combusion engines, it must compress air to a minimum of say 10 bar, partially burn it to expand its volume, and then expand the enlarged volume through a separate set of cylinders back to atmospheric pressure. Somehow the two systems of pistons appear to be integrated to save energy.

However, since ICEs use a similar compression ratio it's hard to imagine the new scheme could be more efficient than these to any significant degree. But somebody is apparently willing to bet a lot of money that they will be, so I guess I'll have to wait for more information before I make a final judgement.

As opposed to the ICE, the addition of the cylinders to store compressed air from an external source is allowed. However, this appears to be a separate "optional" item, just like "extra batteries" transform a "regular hybrid" into a "plug-in hybrid", although in this case a minimum of air reserve may be required.

Plug-ins store all the "reserve" energy at the same potential as that which is required by the electric propulsion system. On the other hand, the air storage system requires that reserve air be stored at a potential (pressure) many times that which can safely be used by the vehicle. Letting it down from storage pressure to the operating pressure is a significant "exergy" loss.

I think we're coming to the end of the days when we can afford to travel long distances in heavy "personal vehicles" and will have to do most of our travelling using collective modes of transportation. Small "golf carts" whether they are powered by electricity stored in batteries or in air cyclinders could still be a form of completing the last few miles of the journey at low speeds but would not necessarily need to be privately owned. In either case, more electrical generation capacity will be required.

As an advocate of a new renewable technology on the "supply-side" of the equation (producing electricity via the "Atmospheric Vortex Engine") I can understand the frustration of Louis Arnoux in getting his message across. In the case of the AVE, the last criticism that is invariable pulled out of the closet after all other concerns are addressed, is that the "vortex could escape from its moorings and hurt somebody", demonstrating either a complete lack of understanding of the physics of the process or any knowledge of the stages of development of new technologies, or both.

Look up external combustion cycles (Ericsson, Stirling, Brayton, etc) on wikipedia. In general they have much better efficiencies than ICEs. Theoretically they can go up to the Carnot limit.

HvyOilGuy: Perhaps you can clue us into the Atmospheric Vortex Engine?

A couple of years ago I read a few papers guy a guy trying to sell that idea (or something similar I think).

The idea was an extension of a solar chimney. In a solar chimney you build a tall hollow cyllinder. Intruce hit air into the chimney -presumably from solar heating of the ground layer of the atmosphere, and you get a chimney effect. The higher temperature within the chimney means the pressure drop per unit of altitude is lower inside the chimney than outside. Energy can be extracted from the air flowing up the chimney. The problem is that the thermodynamic efficiency is proportional to its height. In the case of natures heat engines hurricanes/typhoons the warm air is exhausted at high altitude -50C or so, so a thermodynamic efficiency of maybe 30% is possible. It is of course infeasible to build solar chimneys several kilometers high. The idea was that by spinning the air the vortex could (on paper at least) extend the effective height of the chinmey several fold. In essence, if the concept was working as planned, a tornado is attched to the chimney. People dismissed the idea with comments about the impossibility of controlling weather etc. The real questions that should have been asked were how high above the chimney the effect could extend, and in what sort of wind fields is the vortex likely to be shed?

I would recommend that a compressed gas company such as Air Products or Matheson sponsor a Soap Box derby event where they give kids cylinders of liquid nitrogen with which they can mount to their racer and then couple the output valve to whatever kind of engine or propulsion device they want. Whoever gets the furthest on a cylinder wins.

Or probably safer to only involve college students and do the Solar Challenge with compressed air or liquid nitrogen instead of the sun.

Seriously, each team would get one cylinder and let the creative juices take over. We used to go through scores of cylinders of LN2 a day for basic research and this seems to as good an academic engineering research topic as any other. We will see a few injuries for sure, but that never stopped the progress of science.

Chappelle: "Mars bitches!"

Thats not a bad idea really :-)

List,

External combustion engines are very real, but not common.

Rather than grasp at the straws of "perpetual motion scams" and try to dismiss it as hype, here is another attempt to explain what is going on.

Some of you will remember the "Mamod" model steam engines that were either a table top stationary model or a traction engine. These had a little oscillating steam engine, that ran on the steam from the brass boiler. You lit a spirit burner under the boiler, and within 5 minutes the little engine was buzzing and the wheels turning.

Now some model engineers, found that it was more convenient (and safer) to run their model engines on compressed air, when exhibiting them at model shows. So they would disconnect the steam pipe from the boiler and connect it up to a flexible airline and run a small electric compressor under the table. The models would run all day, without having to worry about hot steam and spirit burners.

The energy powering these models ultimately came form the fuel being burned at the power station.

Unfortunately, the engines running on compressed air were very limited in power, but one way of boosting their power was to run them on heated compressed air.

Instead of a straight pipe from the compressor, the pipe is replaced with a coiled length of copper pipe onto which you direct a propane blowtorch. This produces an immediate boost of power from the model engine.

So the bulk of the energy driving the engine is now coming burning fossil fuels in the blowtorch, plus the air from the compressor.

It is now a simple mechanical step to see that this could be developed such that engine is capable producing sufficient power to run its own compressor and no longer needs the electric compressor. The only thing needed to run it is a source of external heat.

This is what is happening in the MDI engine. BUT - It's not a very efficient use of the heat energy. In real terms this is going to be reflected in the miles per gallon achievable from the vehicle.

A 3 page article describing John Ericsson and his engines is here:

http://www.stirlingengines.org.uk/pioneers/pion4.html

Unfortunately I think you are more than generous in accepting Louis's word that this product exists in anything like the specification he quotes. Do yourself a favour and have a look at http://aardvark.co.nz/daily/2001/0216.shtml and http://www.nzherald.co.nz/section/3/story.cfm?c_id=3&objectid=10115833 to get an appreciation of previous scams Louis has foisted on gullible investors.

You might also want to look at http://www.thefuture.net.nz/index.htm to get a feeling for the professionalism Louis brings to the market.

There seems to be something fundamentally wrong with the idea of an air car. Compressed air and compressed air motors are a pretty mature technology (100 years). Compressed air is a major cost of many industrial facilities. There has been a strong incentive to reduce the cost of compressed air for much of that 100 years. Now, I understand that the energy cost assumed today by industrial users for the provision of work done by compressed air is about 7 hp of electrical power to compress the air for a 1 hp air motor. This would seem to make air motors grossly inefficient for cars.

If the designers of the air car have produced such a large reduction in the energy cost of compressing air, why are they not getting rich immediately by revolutionizing the use of compressed air in industry, rather than slowly by trying to change automotive technology?

Guys n Gals

There are a couple of things you overlook which may make the whole thing "add up"

1/ The compressed air has the approx energy of 1 gal of petrol (don't know if US or imperial)

2/ The engine is 90% efficient (quite believable) so fuel equiv is 3 gals (cf ICE efficiency of 30%)

3/ The car is extremely light and small

So getting 120 Mile range on 3 gals of fuel for a small light vehicle is quite achievable,

Also the expansion process is an approximation of an isothermic expansion, it does this by

absorbing heat from the surrounding air (this is also achievable, cf your 100kW ICE as say 30% effic

is disapating approx 200kW!) so yes in a way it gets energy from thin air (though will limit the range in the antartic)

As for the argument that it simple moves carbon emissions from tailpipe to chimney a/ this isn't true here in NZ (as 70% of our electricity is renewable) and b/ This is a tiresome argument for inaction as it is easier to fix a centralised carbon emmitter than several million mobile ones!

As an aside I happy to see that the mainstream car manufacturers (GM, Chrysler with prodding from AFS Trinity) have finally come to the conclusion that the future is electric cars via hybrids, with 80% of journeys under 40 miles the obsession with range has muddied the waters, face it the reason the fossil fueled ICE is so hard to replace is because it is the solution that offers the least compromises, this, not conspiracy has stalled development of alternatives, the "consumer" is an ignorant and relatively lazy beast.

I love to "smack about" all those marketing execs who have misled the public with a clean "hydrogen" future, it was all spin as this simply did not make sense, I'm sure they saw it as a way of appearing to develop the "silver bullet" solution while doing business as usual (ignoring EROEI concerns and half a trillion dollars worth of infrastructure, assuming they could get the cars to work).

Historically Hydrogen will be seen as commercial fraud in much the same way as bio-fuels will be seen as government conspired frauds.

What I'd love to see now is the development of an international standard non-contact in-ground charging point which means you can simply park your car over it and it drops and aligns an inductively coupled connector (so the lazy and ignorant beasts don't have to remember to plug their cars in)

Regards

Neven MacEwan B.E. E&E

Sorry Neven911--your claim of 90% efficiency is *not* believable, especially on a mobile source in a confined space. There are always mechanical/parasitic inefficiencies such as friction, valve entrance losses, etc that rob power in addition to "process" inefficiencies such as temperature differences required for heat transfer. This is especially true in gas-gas transfer.

So unless the design includes a huge amount of heat transfer surface, and multiple (more than 2) expansion stages, "isothermal" expansion cannot be approached. This amount of equipment would be impossible to put in the space allowed for a small car.

HvyOilGuy

I'd just like to say that the 90% efficiency is not my claim, also the heat transfer is not gas to gas, (mainly being solid to gas through the cylinder walls) the compressed air comes in at ambient (when not preheated), As far as I have read the exit gas is near atmospheric and > -10 degrees C so theoretical efficiency could be high. I don't see why on the basis that an ICE disapates 10s of kilowatts though a radiator (with a nominal 70-90 degree temp diff) an air car can't absorb significant energy with the same heat exchanger and a nominal 30 degree diff)

Then again I might just be an idiot

Neven

Recovering 90% of the added heat as work seems much more reasonable, and I am inclined to give it the benefit of the doubt.

Even given that, the sum of the claims is not credible.

I did have some interesting thoughts during my bike ride. For the moment lets suppose the MDI (Ericson) engine is efficient compact and cheap enough, but that unlike typical ICE today it cannot deliver high power on demand. So it may be sized to produce just enough power to sustain cruise, but would be seriously challenged for acceleration. If you only need occasional bursts of high power, it might be acceptable to pay the cost of low efficiency for that boost. The compressed air storage could provide that boost. Presumably the need for occasional high power bursts can be cheaply supplied by compressed air. Unfortunately that doesn't sound like their thinking.

Everyone seems to overlook that a bit of "bait and switch" has gone on at MDI.

I was a member of the original Yahoo group that was in support of the "Air Car", and in the first half decade, there was no mention of carrying these compressors onboard and making the air "as you drive" by way of some other sort of fuel input.

Demonstrating this fact is that in the early days, the promotional hooks always said "no tailpipe emissions" (impossible if your carrying fuel and burning it onboard) and no fossil fuel consumption. The no FF may be true if your intending to carry onboard a non-fossil fuel (bio-fuel, hydrogen made by renewables, etc.) but by now we are talking about a whole different consumption dynamic than was originally promoted.

With a heat source on board the car, we are back to your basic debate about internal vs. external combustion engines, i.e., the efficiency of steam, Stirling, Ericcson, hot air engines vs. gasoline/Diesel or biofuel internal combustion. The amount of math and research that has been done on this technical issue has filled volumes for over a century, so there is no real news here.

Many years ago, one of my uncles pointed out the problem with external combustion, it was one of those "AHA!" moments for me: On an external combustion engine, the heat from the combusion has to pass through some time of wall to be put in the working fluid. There must be losses in that transaction. On an internal combusion engine, the combustion fluid IS the working fluid! That one physical limitation of the external combustion engine, (two substance, one heat making and one working fluid) makes all the difference in the world. The air car does nothing to overcome that.

RC

RC

Heat transfer though the wall between the combustion and the working fluid is not the cause of "loss", the loss is in the exit gas temp (think in terms of energy conservation). Large coal fired steam turbines are 40+% efficient, if you do a combined cycle gas turbine feeding a steam turbine then eff of over 60% are possible, use the waste heat to heat up water and you have a CHP plant of 90% eff.

Efficiency is one of those mis used words, energy transformations are 100% efficient, (energy is neither created nor destroyed) but "efficiency" means the ratio of target energy form/input energy

Sorry to dis your uncle but the theorically most efficient heat engine (a stirling cycle) is external combustion.

Neven

Neven911.

First, don't worry about uncle, he does alright...:-)

You said,

"...the theorically most efficient heat engine (a stirling cycle) is external combustion."

Then we should see them everywhere right? After all, the Stirling had a decades head start on the internal gasoline engine! And yet, no automaker from the birth of the industry to now has made them viable. Why is that?

Given the touted Stirling efficiency, then, we should at least see them, and not the steam turbines in stationary systems for electric power production. And yet, we don't. Why?

Having said that, you would think I am dissing the Stirling engine. The theory of it is very good, and I still have high hopes for it....but to this date, even fantastical ideas such as the "air car" seem to hold more fascination as an internal combustion engine alternative than the Stirling for transportation and alternative energy production. Why?

Allow me to have a few comments on what I have been able to learn so far, complete with errors in thinking, and anyone who would like to have a bit of 'back and forth" on this, please do, because I am only a student, not a master, and am still incorporating any new thinking on this into my logic! :-)

For transportation use, a motive power unit has to be "efficient" in many areas (I am using the word "efficient" in the broad sense as understood by the layman, and not in a narrow thermodynamically "mathematical sense".

The motive source or "engine" must be efficient in (a) power produced per weight (b) power produced by volume (size) (c) power produced by amount of fuel consumed, and in the broader often non technical sense, (d) power produced by dollar spent on it's construction and (e) power produced by it's complexity of construction, including use of exotic materials or need for exotic fuels of combustion.

As we learn every time we attempt to find alternatives to the internal combustion engine for use in transport, the above five points are a tall order to fill. The internal combustion engine does it shockingly well. Cheap to manufacture, using commonly available metals, reliable and reasonably simple in construction using a fuel that is (after the oil industry built the infrasture) commonly available, and very compact in size and weight for it's output, it is difficult to easily better.

It's weakness is that is not efficient in the "narrow" thermodynamic sense that you describe, i.e., it allows much of the heat to escape without doing useful work in (a) combustion (b) cooling and (c) internal friction. In other words, much of the heat goes into into heating the oil and water used to lubricate the engine, and the rest goes out the tailpipe. Point (a) is a huge problem, because the combustion is not continous but intermittent and high speed, making the combustion process very hard to optimize. This not only wastes fuel but makes the engine "dirty" in the sense that fuel goes out the tailpipe in unburned condition as pollutants.

This is what makes the "external combustion" engine seem to be such a promising option. The steam cycle, Erricson cycle, or Stirling cycle engines all rely on continous and more easily controllable combusion. The idea is that these type of engines would be much more efficient and cleaner becasue the combusion process could be optimized and contained, thus doing much more useful work per unit of fuel consumed.

Why has this not be case? Let us take the engine that was touted in the post I am replying to as "the most efficient".

http://en.wikipedia.org/wiki/Stirling_engine

The Stirling engine is indeed thermodynamically efficient, but as the very good introductory article at Wiki points out, is not so efficient in "specific output", that is, power produced per weight and volume of the engine. Most external combustion engines in fact are "low specific output" engines.

Evidence of this is easily seen in the size and weight difference between older steam railroad locomotives and newer Diesels. The Diesels are much smaller and lighter. The newest generation of Diesels have fantastic specific outputs, due to advanced turbocharging and intercoolers and computer designed combustion chambers and fuel injectors. The combustion process, though intermittent, is very optimized given the limits of what can be done with intermittent high speed combustion.

It has been argued that steam engines in electric power plants are much more efficient, and indeed they are. However, all the tricks of the "critical steam" trade have been applied, in superheating the steam, in recapturing waste heat, in recycling heat, etc. All this is heavy in wieght and big in scale, but a stationary power plant cares little about weight and size, and is simply trying to optimize heat capture and usage (the narrowly defined thermodynamic "efficiency").

Remember also that stationary steam plants (along with industrial combustors and furnaces) have refined the art of continous combustion to an art form. Thus, we should have all the tools needed to build a perfect continous combusion external engine for transportation.

So if we take the absolute optimal continous combustion burner given current knowledge, and absolutely most efficient converter (engine) in something like the Stirling engine, we should have the perfected prime mover, the most efficient heat engine as transport engine that could be built.

Are there any barriers? Well one, and it's big. The absolutely perfected combustor must still get the heat into the working fluid. It will have to pass the heat through the solid wall of a heat exchanger without losing much of it. And if the heat is not to be lost at the end of the cycle, it will have to pass it back into the cycle by way of heat exchangers or "recuperators" of some type. The efficiency of these two transactions set the absolute limit to what an external combustion engine can do. It is and has always been the great limit to external combution engine "efficiency" as a whole. No matter how efficient you make the combustor, if you cannot get that heat through a solid wall into a working fluid, and back into the cycle to contain the heat losses, you simply cannot increase the efficiency of the engine.

Every trick has at one time or another been attempted to increase the heat transfer through a solid wall and reduce the limits imposed by this barrier (because it cannot be done away with, it can only be reduced).

Ultra thin wall heat exchangers have been tried. Exotic metals have been used in heat exchangers. Exotic working fluids have been attempted. To make a Stirling engine more of a "high specific output" engine helium as a working fluid has been proposed, but this is an expensive and exotic solution.

A Stirling engine will run on hot air as a working fluid. But the weight and volume (size) of the engine will be very high compared to a modern Diesel, and your still going to have to supply heat from somewhere. The engine will be "thermodynamically efficient. But it will fail on the issue of specific output, being large and heavy for the power it produces.

One of the more promising ideas is Stirling Energy's use of solar energy:

http://www.stirlingenergy.com/default.asp

Needless to say, this is not a system that applies to transportation.

So, again, in an external combustion heat engine, we are completely limited by the wall of the heat exchanger. There are other losses of course, but the efficiency of the tranfer in the heat exchangers of whatever type are the ABSOLUTE limiting factor to the overall efficiency and specific output of external combustion engines.

(Neven911, I hope you can see that I did not take uncles word at face value...I have spent some time on this....:-)

Thank you

Roger Conner Jr

RC

Roger

I was responding to your statement about "efficiency" by which I presumed you meant "thermodynamic efficiency".

Neven

This tapdance is getting a bit tiresome.

First, let's be clear--CHP efficiencies are NOT RELEVENT in this discussion, since there is no magical "heat pipe" involved to heat your granmother's basement. We are talking strictly about "thermal heat engines" in which "work" delivered to the rear wheels of the vehicle is the only useful product.

The most efficient heat engines devised by man on a commercial scale are combined cycle turbine natural gas fired plants, which, as you correctly state, have efficiencies bordering on 60%. These involve alloy blade technologies developed to withstand the highest temperatures possible, are highly integrated, have virtually no heat loss to ambient, except for the exhaust gas, and occupy a large area of ground.

If you are here to tell us that the new engine developed for your mini-car, as determined on a "stand-alone" basis, even remotely approaches this efficiency, you are indeed, an idiot (and so is anyone else who would believe such a notion).

HOG

People are getting fired up over the energy efficiency of the burner/engine, whereas it looks to me as though the main factor influencing the strong fuel economy is its ultra light weight, good aerodynamics and low speed.

The "Loremo" (www.loremo.com) is an example of a similar car, due on the road in 2009, that is expected to achieve around 2L/100km. The Loremo just has a small, efficient diesel engine - nothing fancy. The magic occurs in its reduced frontal area, low coefficient of drag, and low rolling resistance (due to thin tyres and low weight). Minimise these parameters and you can power the car with even a conventional ICE and achieve "miracle" fuel efficiency (VW did a tiny concept car, a 2-seater called the CC0 that achieved 1L/100km in trials). Better still, sell the vehicle as a city commuter "tuned" to an optimal speed of 50-60kph, and you further reduce the need for good aerodynamics (fuel consumption due to aerodynamic drag is a function of velocity squared, so reducing velocity can massively reduce fuel consumed due to wind resistance alone - ask any cyclist!).

Consider that small hatchbacks on the market today can really achieve 6L/100km while driving at 110kph. These cars typically weigh 1000kg or more, have wider tyres than necessary, and have a large frontal area. Put little pizza-cutter tyres on it, cut down its weight by 50% through smart materials and frugality, and make it shaped like a Ferrari for low frontal area. Now, couple this with a smaller engine and drivetrain such that optimum efficiency occurs at 60kph, and you can engineer a 2L/100km car with relative ease.

(It's probably no coincidence that the designer of the OneCAT was also a Formula 1 engineer - the same governing equations apply to maximising speed as maximising fuel efficiency, you're just optimising a different variable.)

Since the main business of IT-MDI appears to be variable-fuel stationary power supply, it strikes me that *perhaps* they are seeing the OneCAT as simply a good place to market their variable-fuel system. The overall efficiency of the mobile fuel/air/burner/engine may end up only equivalent to an internal combustion engine, but placed in a lightweight aerodynamic car, you have a cheap fuel efficient vehicle for the masses, that can be fuelled on various combustibles.

Sounds alright to me.

There is nothing new about this tech. These air cars have been running around. The problem is design regulations. How to store such a massive amount of PSI. The problem here is not that it cant be done, because it has, and the tanks hold enough C.A. to power the vehicle for 6 hours, but that no one will insure them, or pass them for safety regs. I have made a few of these air cars and a boat myself. It is very easy. Getting the Tank is the Hard part.

Here is a link to the companies history http://www.theaircar.com/aboutmdi.html

Another big problem I had was recharging the tanks. In the end I gave up because it was much more expensive than battery power storage, and almost as slow. This type of car is defiantly not suited to all uses, I see them more as a way to reduce air pollution, rather than as a way to reduce energy dependance.